|

@sia_josephine

The Adventures of Sia, Zuko & Richard Parker |

|

@sia_josephine

The Adventures of Sia, Zuko & Richard Parker |

|

< back Designing my 3D printed cat wheel... |

This started as a personal challenge as I, a.) Made an impulse decision to buy a 3D printer, b.) Wanted to learn Fusion 360 to make something useful, and c.) Wanted to replace my existing cat wheel. I had already purchased a cat wheel but it spun poorly, didn't have a stable base, and I hated the fact that they used fiberglass in the rails without warning people and it messed up my hands. I won't name the company, but they are the first one to show up if you Google "cat wheel". People asked to buy the STLs when I posted a video on Facebook, so I've uploaded the files on Cults3D. If you purchase my files, you agree to not sell or share them, including the printed wheel itself.

Buy STLs on Cults 3D*

*(These are files for 3D printing, you won't be shipped a cat wheel!)

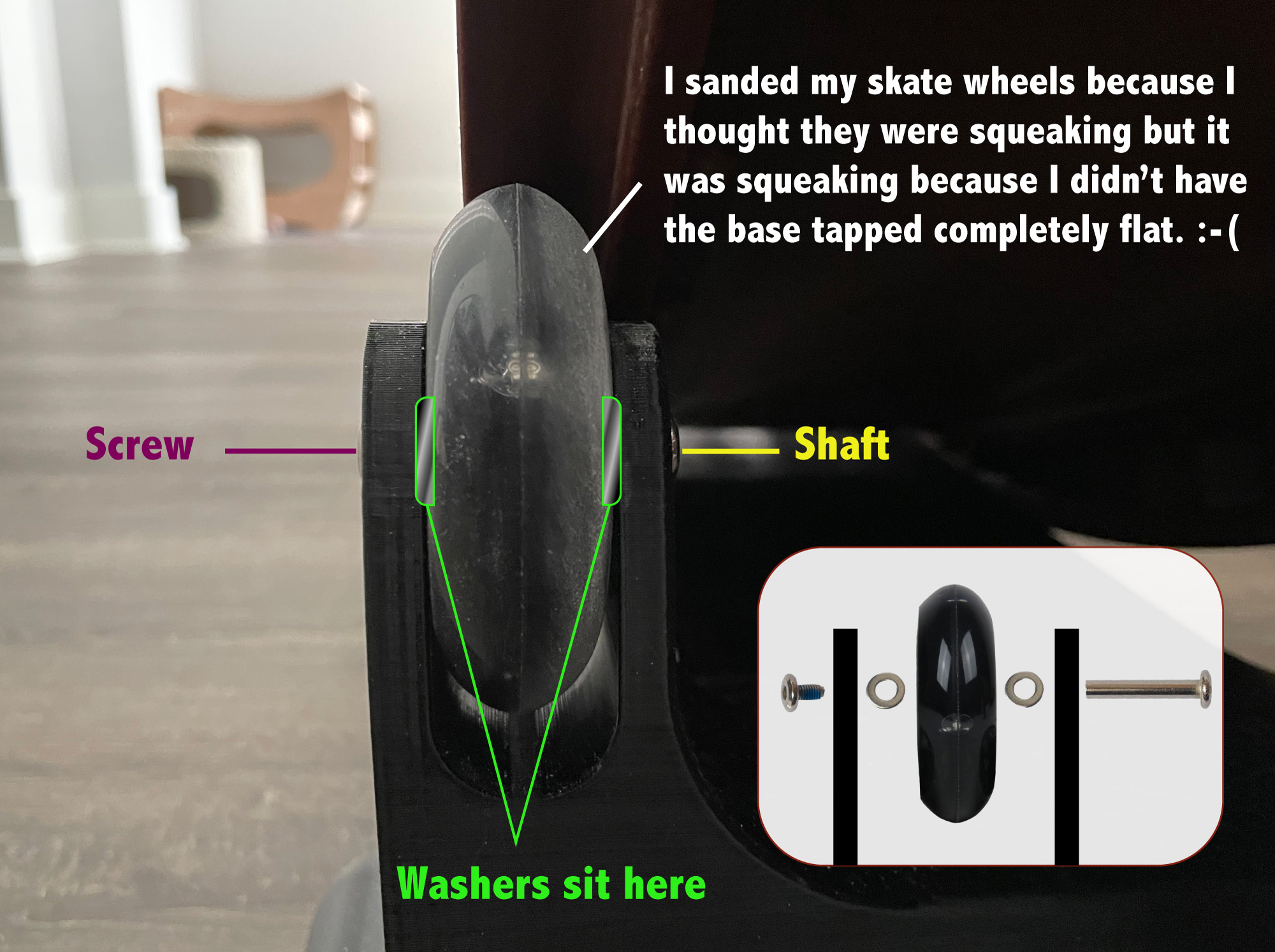

Please scroll down and read over the hardware needed. This isn't a cheap project, but you'll end up with the satisfaction of making something awesome for your amazing cat(s) and having a sturdy cat wheel. Oh, and you can make it any color you want! I can't tell you the exact cost of this. The parts outside of the filament cost me around $100 but you can certainly shop around. How much filament you will need will be determined by the settings you use. I used a lot of infill to make mine heavy; I picked a weight I wanted and adjusted the slicer until I achieved that weight. I found photos from July 2021 of the rails (with supports) and tracks sitting on a scale and they were each 162 and 163 grams, respectively. I've re-sliced the base pieces to get a weight and it came out to 4,880g, but you can make it lighter than that. Somebody who printed the wheel used a lot less infill than I did. I used 15% infill on the base corners and 10% on the three pieces that connect the corners. I used 4 walls and 6 top and bottom layers. My wheel took around 13 spools when you add it up. GST3D PLA+ was selling at $8 a spool at the time.

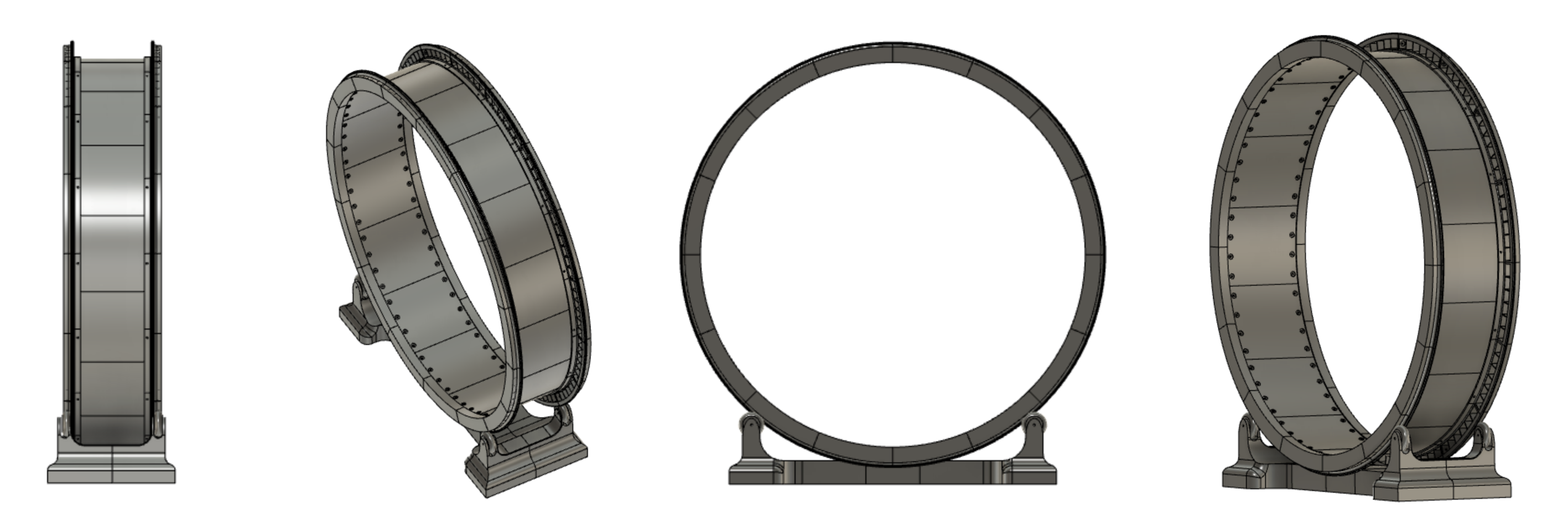

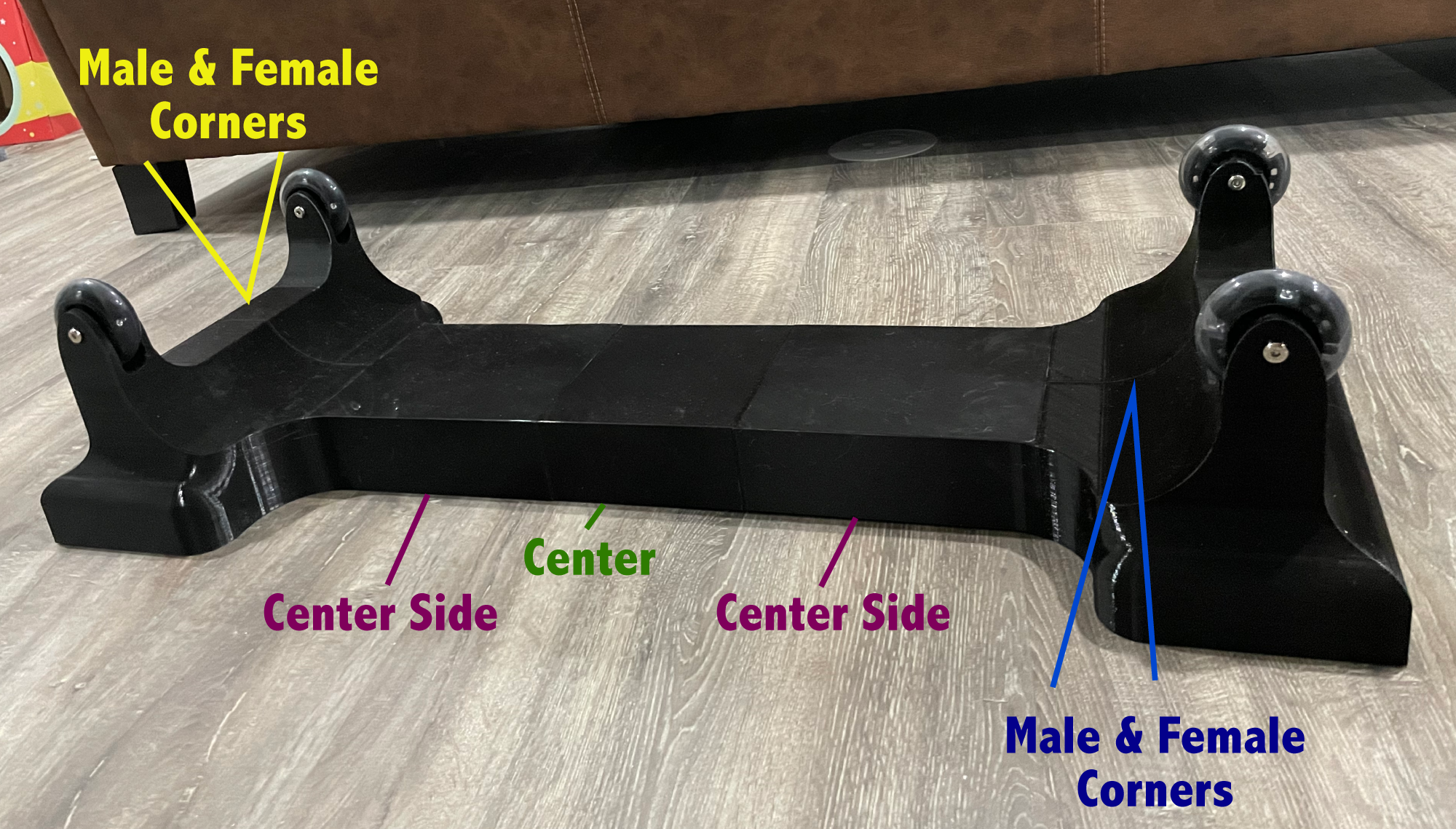

I designed this cat wheel and printed it on an Ender 3 which has a build area of 8.7 x 8.7 x 9.8" (220x220x250mm). Some of the pieces take up the entire build plate, so I do not recommend printing this on a smaller printer. You can't scale it either as the skate wheels won't fit in the base. The final wheel measures 4' wide and 4'4" tall. I use prusaslicer and designed the corners to max out my build plate.

Big Wheel Parts

Wheel:

Base:

Hardware and components: (I'm including links to the ones I used, but you can always shop around!)

| Product | Qty needed | # of packs | Price per pack |

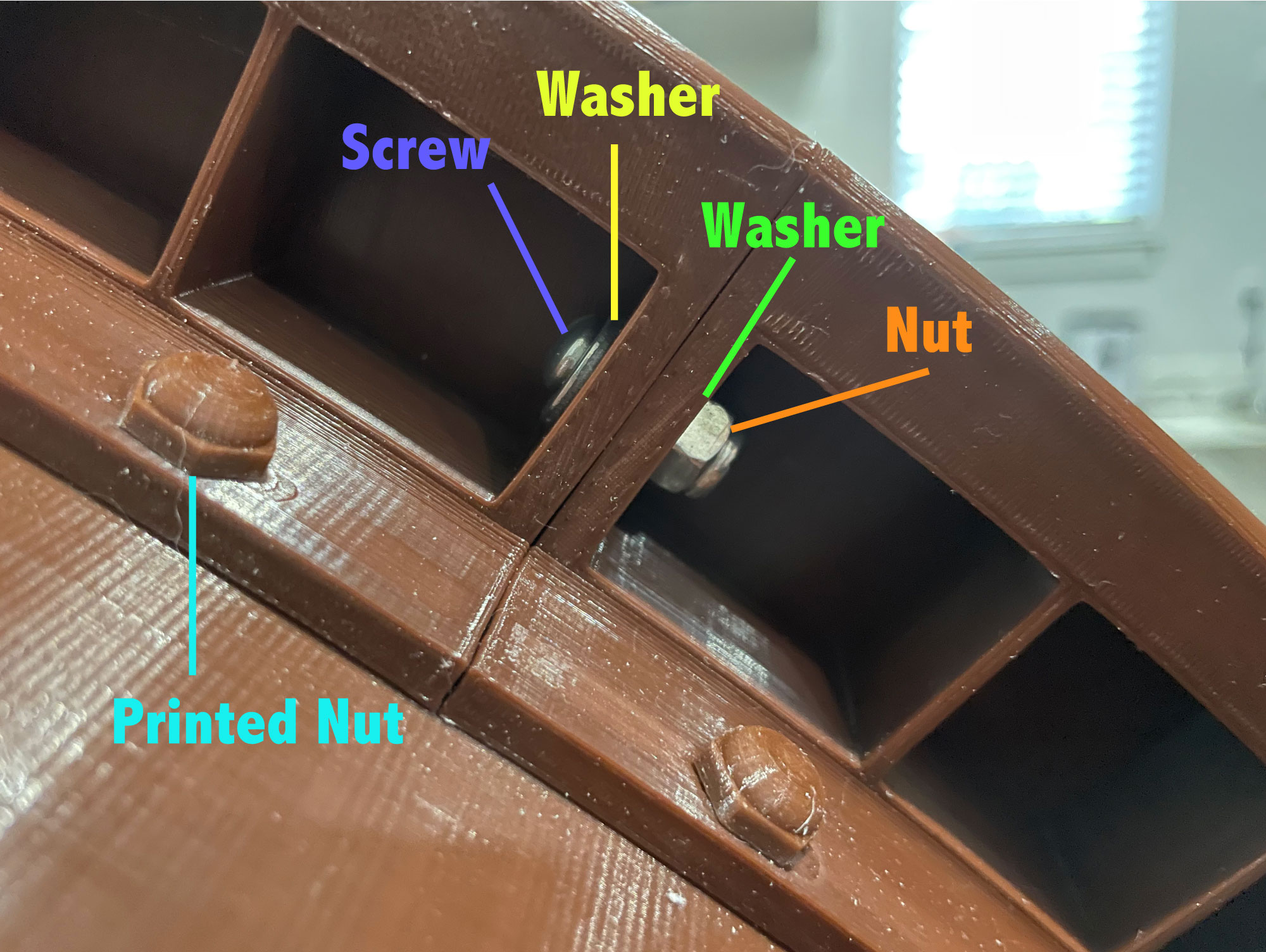

| Zinc-Plated Steel Pan Head Phillips Screw 12-24 Thread, 3/4" Long |

32 | 1 (100/pk) | $8.09 |

| Low-Strength Steel Nylon-Insert Locknut Zinc-Plated, 12-24 Thread Size |

32 | 1 (100/pk) | $7.00 |

| 18-8 Stainless Steel Washer for Number 12 Screw Size, 0.234" ID, 0.5" OD |

64 | 1 (100/pk) | $3.40 |

| Total: $18.49 | |||

| Product | Qty needed | # of packs | Price per pack |

| Zinc-Plated Steel Pan Head Phillips Screw 12-24 Thread, 3/4" Long |

32 | 1 (100/pk) | $8.09 |

| Low-Strength Steel Nylon-Insert Locknut Zinc-Plated, 12-24 Thread Size |

140 | 2 (100/pk) | $7.00 |

| 18-8 Stainless Steel Washer for Number 12 Screw Size, 0.234" ID, 0.5" OD |

192 | 2 (100/pk) | $3.40 |

| Extra-Wide Truss Head Phillips Screws Passivated, 12-24 Thread Size, 5/8" Long |

128 | 3 (50/pk) | $11.82 |

| Total: $64.35 | |||

Assembly

Connect the walkway pieces to the rails with the plastic screws first because it will be harder once the metal rail pieces are tight. Offset the walkway from the rails by two holes.

Then connect all the rails with the metal fasteners. Loose to start and once you have them all in, snug them up. I used a ratchet and Allen wrench to tighten them up.

Once the wheel was put together, I put a dot of super glue under the printed nuts on the walkway, just in case. You don't need to do that if you use metal ones.

If you decide to print the screws for the wheel:

If you decide to use metal screws for the wheel, only use one washer, which will go under the nut:

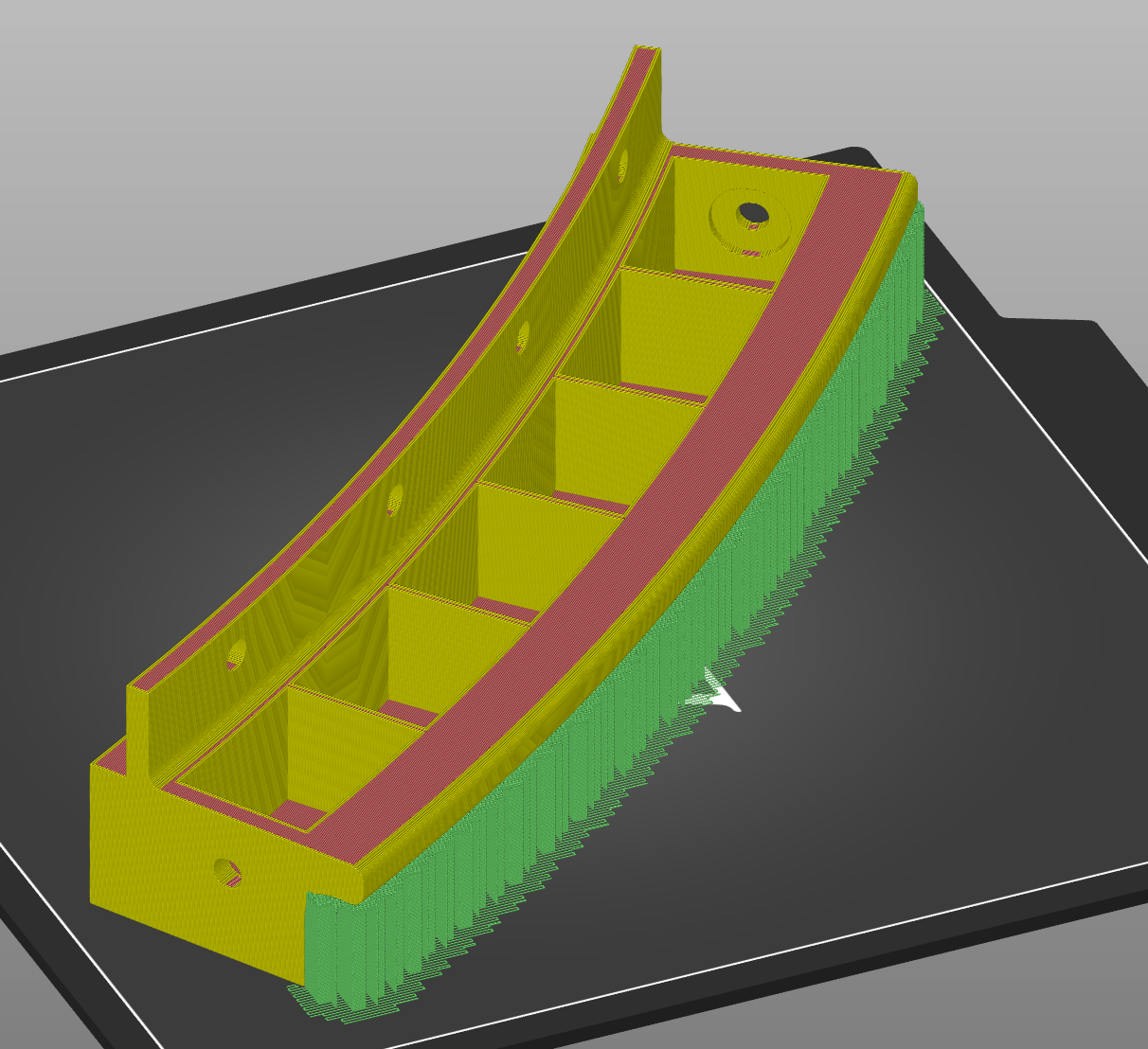

Rails - Print them with the large flat surface on the build plate. The overhang needs supports. I had to gently sand where the supports were after my wheel was assembled but I’m sure there are better support settings than what I used.

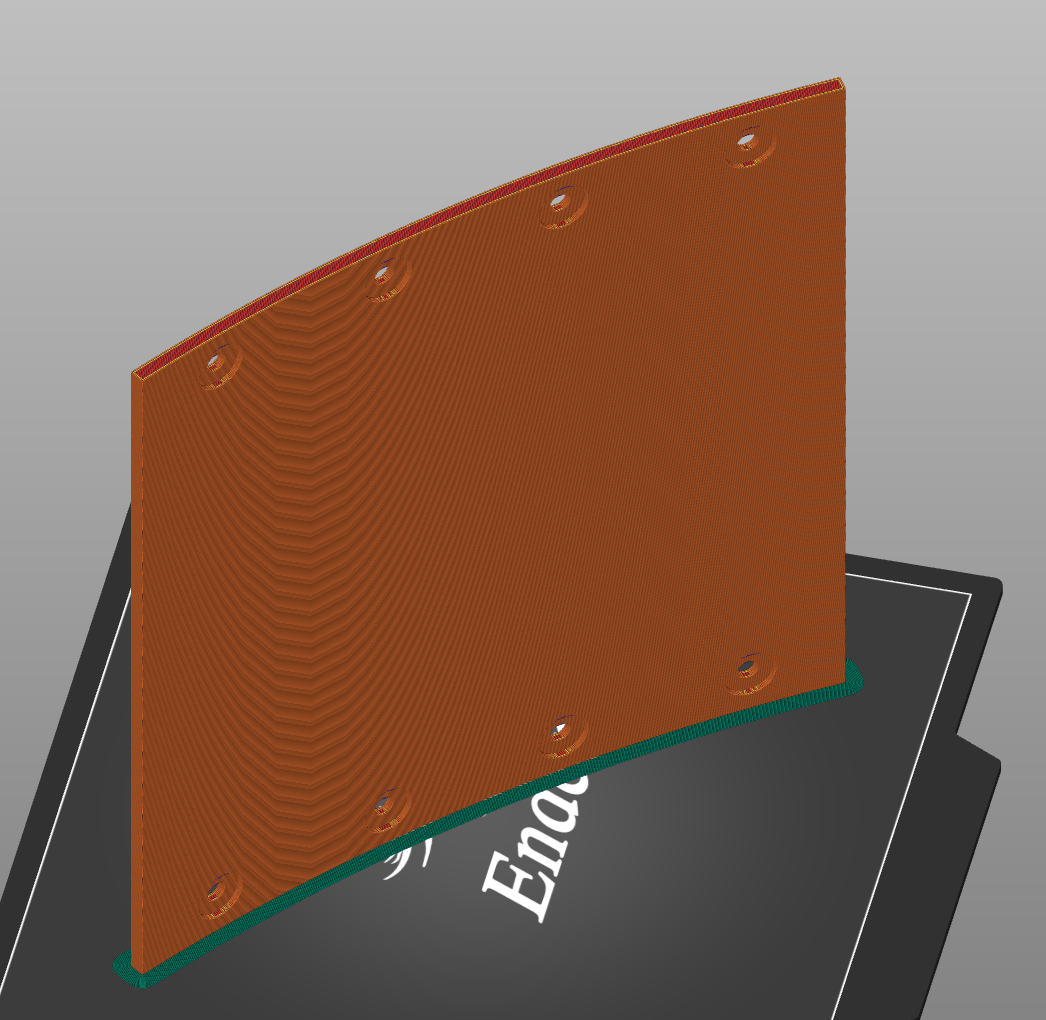

Walkway - Print them on their sides standing up. I recommend using a brim.

Base - Print all as they will sit on the floor accept for the "center side" pieces which you can flip upside down to avoid using supports.

Note: Some of the links on this page are Amazon affiliate links.